Die Zementindustrie steht vor großen Herausforderungen und hat gleichzeitig die Chance, eine entscheidende Rolle bei der Erreichung der klimapolitischen Ziele einzunehmen. Die Zementproduktion trägt weltweit mit ca. 7% zum gesamten CO2-Ausstoß bei und steht daher seit Jahren im Fokus von Gesellschaft und Politik. Zur Zielerreichung beitragen können vielfältige Maßnahmen, wie die Reduktion des Einsatzes fossiler Brennstoffe durch CO2-neutrale Ersatzbrennstoffe, neue Produktionstechniken unter Sauerstoffatmosphäre, Carbon Capture Projekte zur CO2-Einlagerung, die Herstellung von technischem Kohlendioxyd oder synthetischen Kraftstoffen. Eine weitere, seitens der Zementindustrie vorangetriebene Forschungsaktivität und weltweit zu beobachtender Trend ist die Reduzierung des Klinkeranteiles in Zementen.

Download Brochure as PDF

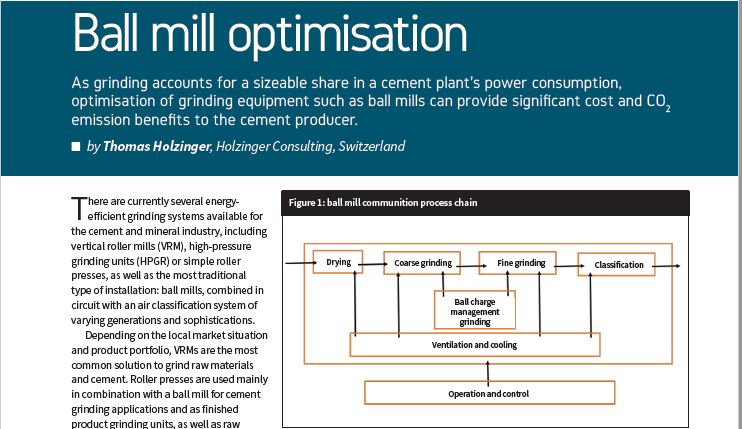

As grinding accounts for a sizeable share in a cement plant’s power consumption,

optimisation of grinding equipment such as ball mills can provide significant cost and CO2

emission benefits to the cement producer.

n by Thomas Holzinger, Holzinger Consulting, Switzerland

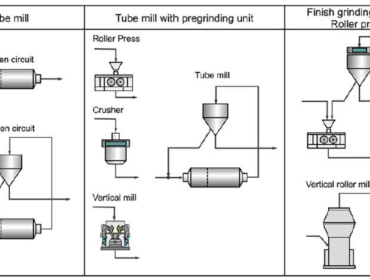

The cement industry uses a wide range of different systems in raw material, coal, and cement grinding. While new plants mainly focus on highly energy‑efficient systems, using roller comminution systems like vertical roller mills (VRMs) and high pressure grinding units (roller presses), less efficient ball mills and combined grinding systems (pre-grinder plus ball mill) are still widely used. Which option to install depends on the local cement market, the product portfolio and raw materials, as well as the relevant operational skills available to maintain such systems.The industry is facing high volumes in every global market and cement pricing is driving producers to

optimise their systems to peak performance. Rising electrical energy costs have created a trend to force plants to reduce their production costs by system and wear part strategy optimisation.

Introduction

A process diagram showing the production line of a grinding system (Figure 1) was discussed earlier this year in World Cement.1 Following comminution, it is of utmost importance to remove the fines – according to the respective product fineness specification out of the mill – as efficiently as possible. This process requires the use of classifiers, which will be the topic of this article.